As global populations surge and traditional livestock farming strains environmental resources, innovators are turning to an unexpected solution—vertical insect farms. These high-tech facilities are redefining protein production by cultivating nutrient-rich insects through automated systems. The concept merges sustainability with cutting-edge agricultural technology, offering a scalable answer to food security challenges.

Unlike sprawling cattle ranches or poultry houses, vertical insect farms stack production vertically in urban warehouses. Crickets, mealworms, and black soldier fly larvae thrive in climate-controlled pods with precisely calibrated humidity, temperature, and light cycles. What makes these operations revolutionary isn’t just their compact footprint—it’s their integration of robotics and AI to manage every lifecycle stage, from egg incubation to harvesting.

Automation drives efficiency at unprecedented levels. Robotic arms sort larvae by size, conveyor belts distribute organic feed waste (often sourced from nearby supermarkets or breweries), and sensors continuously monitor ammonia levels to prevent overcrowding. Machine learning algorithms adjust conditions in real-time, optimizing growth rates while reducing manual labor. One facility in Amsterdam processes 15 metric tons of black soldier flies weekly with a staff of just three technicians.

The environmental calculus is compelling. Insects require 12 times less feed than cattle to produce equivalent protein and generate negligible methane. Vertical farming slashes land use by 90% compared to soy cultivation. When scaled, these systems could divert millions of tons of food waste from landfills by converting it into insect feed—a closed-loop solution gaining traction from Singapore to Toronto.

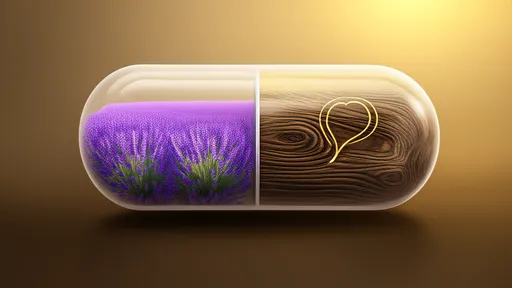

Consumer acceptance remains the final frontier. While two billion people globally already eat insects regularly, Western markets are slower to embrace cricket flour protein bars or mealworm burgers. Startups are tackling this through stealth ingredients—protein powders blended into shakes or pasta—and emphasizing sustainability narratives. Regulatory hurdles are also easing; the EU approved dried yellow mealworms for human consumption in 2021, setting a precedent for novel food approvals.

Investment is flooding into the sector. Venture capital firms have poured over $450 million into insect protein companies since 2020, with vertical farming operations attracting major agritech players. The potential extends beyond human food—insect-based feeds for aquaculture and poultry could disrupt the $500 billion global animal feed industry by 2030.

Critics highlight unresolved challenges. Energy demands for climate control remain high, though some farms offset this with solar panels or biogas from waste processing. Others question whether automation can truly replicate the nutritional diversity of wild-harvested insects. Still, as droughts devastate traditional crops and meat prices soar, vertical insect farms are emerging as a pragmatic—if unconventional—pillar of future food systems.

From sci-fi curiosity to industrial reality, these buzzing vertical factories exemplify how biotechnology can reimagine age-old food chains. As one Nairobi-based farmer quipped while inspecting her robotic harvester: "The cows of the future might have six legs and run on algorithms."

By /Jul 15, 2025

By /Jul 15, 2025

By /Jul 15, 2025

By /Jul 15, 2025

By /Jul 15, 2025

By /Jul 15, 2025

By /Jul 15, 2025

By /Jul 15, 2025

By /Jul 15, 2025

By /Jul 15, 2025

By /Jul 15, 2025

By /Jul 15, 2025

By /Jul 15, 2025

By /Jul 15, 2025

By /Jul 15, 2025

By /Jul 15, 2025

By /Jul 15, 2025

By /Jul 15, 2025